Upgrade Septic System Technology

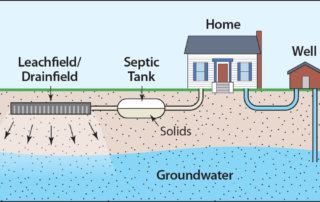

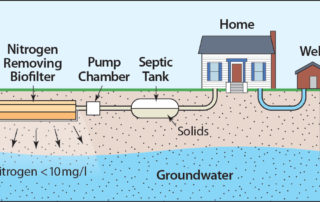

Septic system technology has greatly advanced in recent years, improving the potential of onsite wastewater treatment systems to treat nitrogen. There are a wide variety of options currently in use and more in development – including commercial proprietary systems and non-proprietary systems – both capable of controlling pathogens and removing significantly more nitrogen than conventional septic systems.

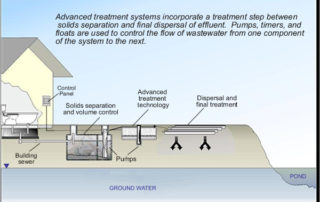

Proprietary nitrogen reducing septic systems – sometimes known as alternative treatment – include a septic tank to settle solids. Effluent flows from the tank to a treatment unit where aeration triggers beneficial bacteria to consume nitrogen in the form of ammonia, convert it to nitrate and then harmless, inert nitrogen gas. In Connecticut, the Department of Energy and Environmental Protection (DEEP) is responsible for oversight of alternative treatment systems. Currently, they are only approved for use in large volume applications and are not permitted for use in residential settings. However, alternative treatment systems have been used in neighboring states of Massachusetts and Rhode Island for many years to reduce nitrogen pollution before it enters groundwater. In 2015, Suffolk County, New York began a comprehensive pilot project to install and monitor performance of nitrogen reducing systems as part of a septic system improvement program to address degraded water quality.

Additionally, promising new wastewater system designs are being tested in Florida, Massachusetts and on Long Island. These non-proprietary systems use gravity and low-pressure dosing pumps to filter effluent through layers of sand and denitrifying carbon media – for example, wood chips or sawdust. This approach is often referred to as passive nitrogen removal (PNR) and does not require an additional treatment unit between the septic tank and drainfield. Use of this technology is limited to existing highly polluted ground and surface waters in Connecticut and will require significant monitoring and fine-tuning of implementation before being approved for widespread use.

Nitrogen Removal

- 50-75%

Cost Efficiency

- $580-$770 per pound of nitrogen removed

Project Costs

- System Cost Range: $10,000-$30,000,

- Operations and Maintenance: $2,000-$3,200 per year

- Monitoring: $200-$300 per year

Strengths

- Removes nitrogen at the source, before it reaches groundwater

- More effective at removing nitrogen than conventional systems

- Long-lasting

- Some proprietary models include service/maintenance agreement with warranty

- Non-proprietary systems are potentially low-cost, low energy, low maintenance options, overall effectiveness and maintenance being studied in Connecticut

Weaknesses

- Systems often require specific lot sizes and setbacks

- Pumps/blowers/mixer technologies require energy and homeowner of service provider maintenance

- High cost per homeowner for proprietary technologies or drainfield construction

- Systems range in effectiveness (50-85% nitrogen removal)

- New system installation does not treat “legacy” nitrogen already in groundwater from older systems

- Few technologies are currently approved for single-family residences in Connecticut

- Community growth and technology concerns make some policy changes challenging